Highest quality standards

Superior quality, accuracy and precision are what you value us for.

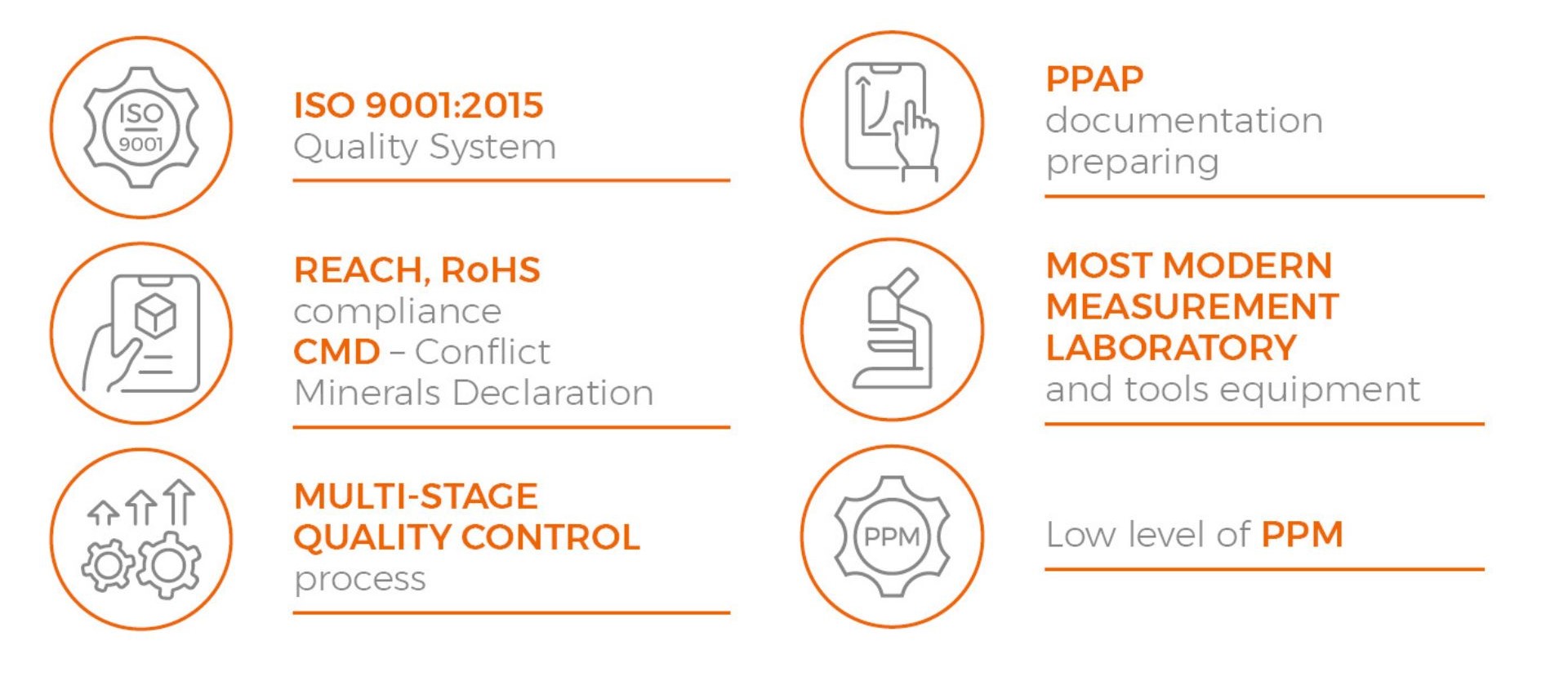

Every product that leaves our plant is thoroughly tested and inspected in a quality control process that covers several stages. This is done from the receipt of stock materials into our warehouse, through each stage of copper or aluminium processing through to the finished product, which we send to our trading partners. Only the purchase orders with a pass from the final quality inspection can be packed and dispatched.

We have state-of-the-art test tools and the Length and Angle Metrology Laboratory, which we use for precise 3D measurements of our products.

Our operations are based on ISO 9001:2015 certification. There is more: our products are developed and manufactured in accordance with the EU Regulations on Registration, Evaluation and Authorisation of Chemicals (REACH), Restriction of the Use of Certain Hazardous Substances in Electrical and Electronic Equipment (RoHS) and the Conflict Minerals Declaration.

The high quality of our products and services is our priority.

We inspect with X-rays

In our production operations, we use an X-ray radiographic system for NDT quality control. The X-ray system is operated in compliance with the Radiation System Operating Permit from the President of the National Atomic Energy Agency of Poland.

We carry out routine ionising radiation exposure checks with personal dosimeters.

- Pursuant to the obligations made mandatory by the Polish Nuclear Law, Article 32c, we hereby declare that our operations with ionising radiation sources had the following effects over the last 12 months:

- No negative impact on human health;

- No negative impact on the environment;

- The practice of operation of the radiation source system in our business ensures full containment and prevents release of radioactive material.